Home > Products > Pesticide Production Line

WDG Drying Solutions Specilist

Custom WDG drying solutions, , global agro certifications, pesticide formulation equipment

30+Global Certificates

Smart Drying Gradient Control

Multi-Shape Granule Formation

Custom-Build Your WDG Success

Get WDG machines made just for you, Control moisture perfectly (+0.5%), make 1-20 tons daily, and keep batches pure.

Morphology Customization

Adjustable particle size (0.1–5mm)

Spherical/cylindrical shapes

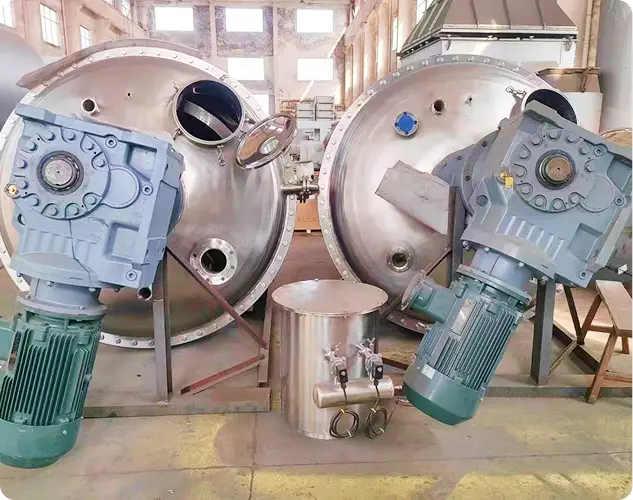

Patented granulation discs

Dynamic airflow design

Drying Customization

Moisture control (±0.5%)

Heat-sensitive material protection

Multi-stage temperature control

Nitrogen circulation

Efficiency Customization

Daily capacity 1–20 tons

Modular production line

Rapid mold-swap tech

LoT-enabled monitoring

Why Longhu Outperforms Standard WDG Equipment?

Our drying systems work smarter to protect your formula and save money, See why smart factories choose Longhu.

Particle Breakage Rate

Drying Uniformity

Line Changeover Time

Longhu Solution

≤2%

(Anti-vibration sieve)

±0.8%

(Real-time Sensors)

1.5 Hours

(Quick-clamp Design)

Longhu Solution

≤2%

±0.8%

(Real-time Sensors)

1.5 Hours

(Quick-clamp Design)

3 Steps to Your Tailored WDG Line

We turn your pesticideformula into customdrying machines in

Prototype Testing

3 smart steps.

1

Requirement Submission

Upload specs or mail samples

2

Prototype Testing

Pilot testing with video verification

3

Full-Scale Delivery

On-site installation & training

Smart Base Configurations-Tweak Any Setting

Start with our expert-tuned drying foundation, then adjust everydetail to match your pesticide formulas.

Airflow temperature: 40–60°C adjustable

Drying intensity: 5–8 kg water/m³·h

Thermal efficiency: ≥75% (waste heat recovery)

Energy savings: 35% lower vs. conventional dryers

Answer Your Critical Concerns

With 50.000+ hours of real-world validation(equivalent to 5+ years of non-stop production), our drying systems deliver

unmatched stability for pesticide granules.

Do you provide installation and commissioning services? What is the response time for after-sales repairs if equipment fails?

- Full turnkey service: On-site installation & process debugging by certified engineers

- Global coverage: 48-hour emergency response in Asia/Africa, 72-hour globally

- Preventive maintenance: Remote IoT monitoring + annual equipment health checks

Can we visit your factory to inspect production facilities and processes?

- Open-door policy: Pre-booked tours available Mon-Fri, with live production demonstrations

- VIP access: For bulk buyers, arrange meetings with chief engineers

How stable are your WDG granules under varying storage conditions (temp/humidity)? Any test data?

- Accelerated aging tests: 40°C/75% RH for 6 months (equivalent to 3-year storage)

- Critical parameters monitored:

Dispersibility: >95% (WHO specification: >90%)

Suspension rate: >80% after thermal stress - Delivery with every batch: Customized storage guidelines + COA (Certificate of Analysis)

Beyond existing pesticide granule types, can you develop equipment for new formulations or dosage forms?

- Formula-Equipment co-development: Collaborate with our R&D center (12 professional talents in agrochemical engineering)

- Proven adaptability: Successfully customized for: Microencapsulated WDG (slow-release)

- IP protection: Sign NDAs before project initiation

Submit your material specs now and receive within 24 hours:

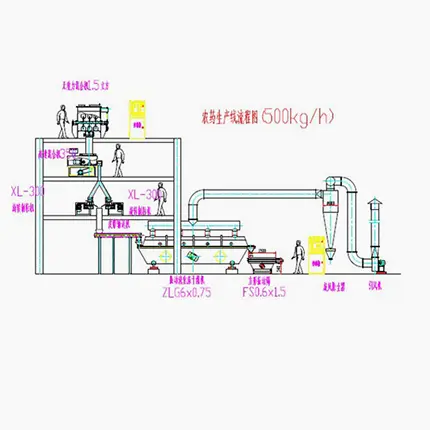

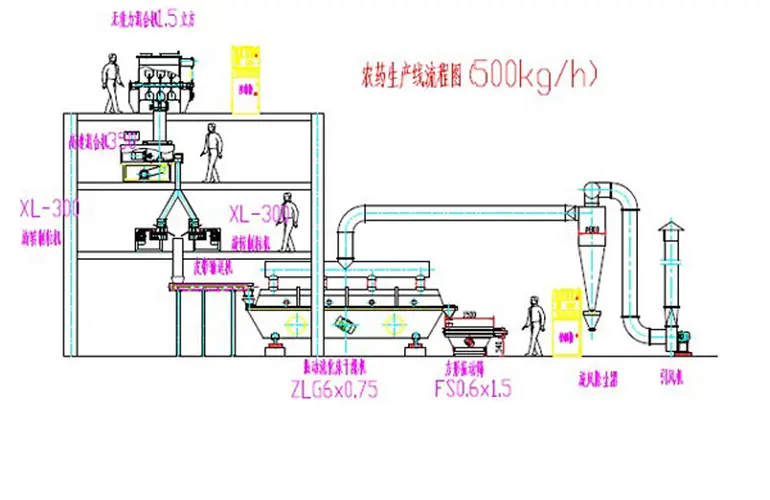

Custom process flowchart

3D equipment layout

Customized pesticide production line